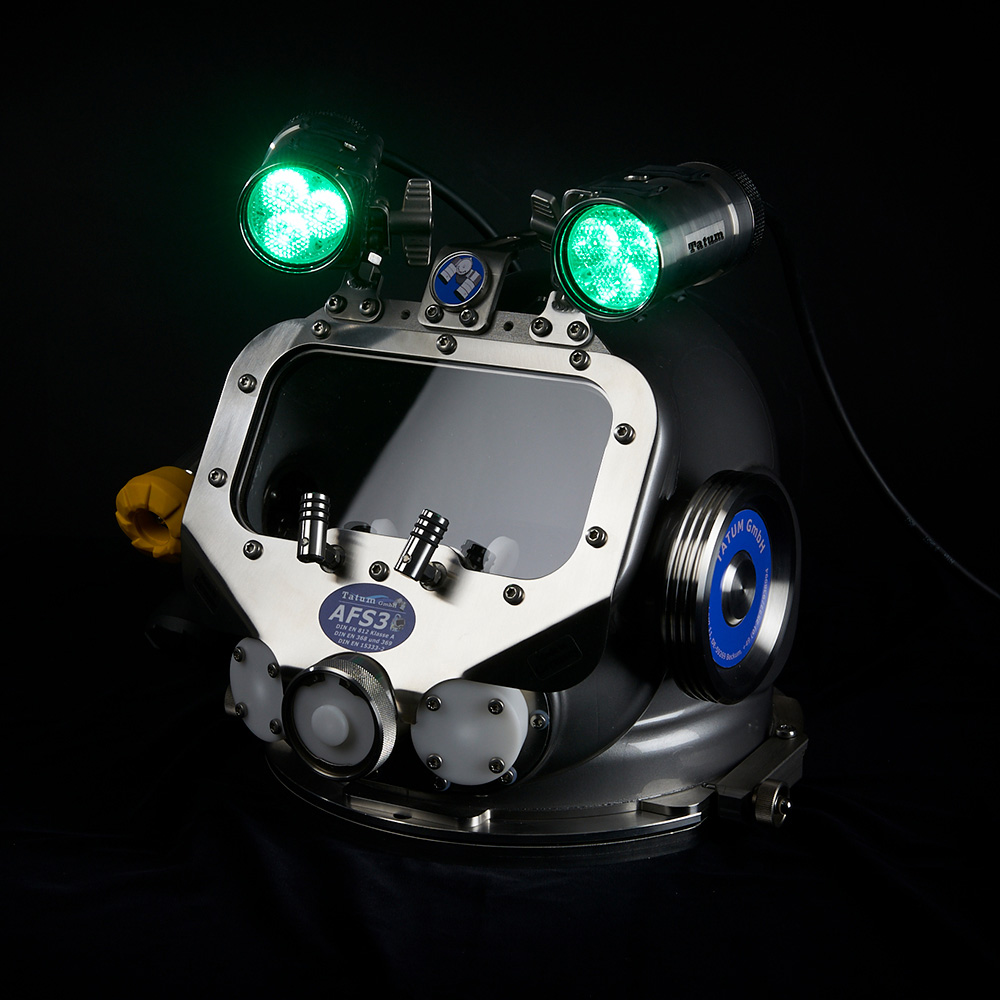

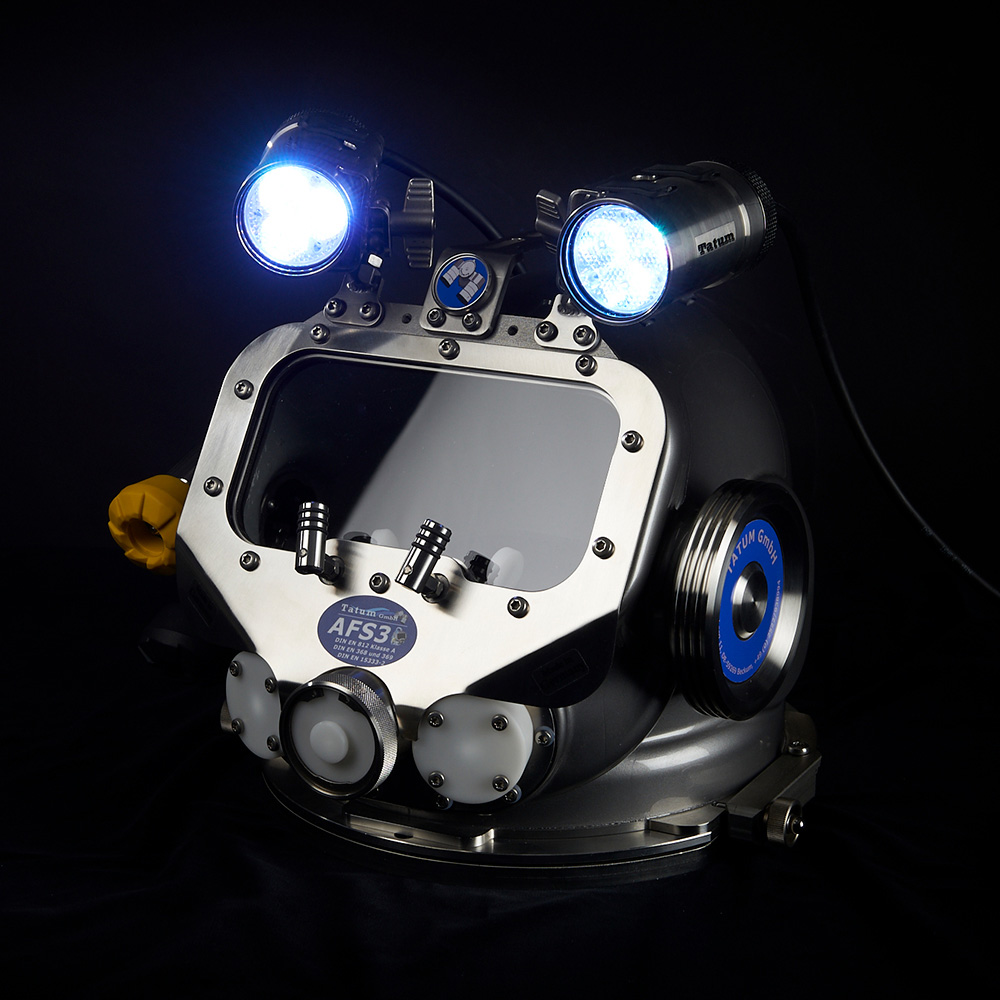

Safer, more reliable, more comfortable:

The Tatum AFS 3.

For professional diving applications, absolutely reliable high-tech equipment is of elementary importance.

That’s why discover now the Tatum AFS 3 diving helmet with constant free flow breathing air technology, which has many advantages over standard diving helmets on the market, offering you more safety, more reliability and more comfort.

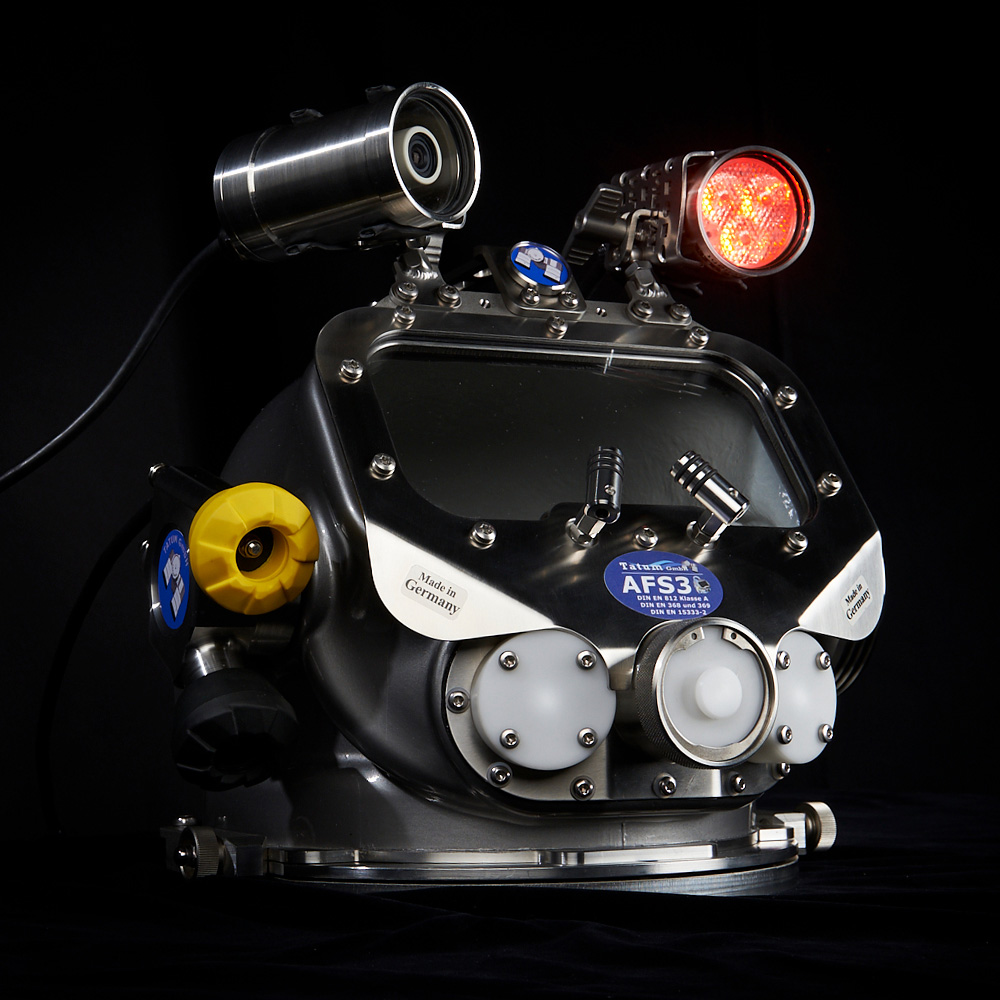

The Tatum AFS 3 can be configured for both commercial and mission divers.

Confident in any situation

- Can be used in all submersible, contaminated media, in liquids with a density of > 1 kg/liter

- Fulfills the highest requirements as a type A construction site helmet for head protection against impact and shock forces

- Convinces by a comprehensive noise protection from the inside as well as from the outside with a damping effect of 25 dB(A)

Safety meets comfort

- Low work of breathing, even with heavy workloads

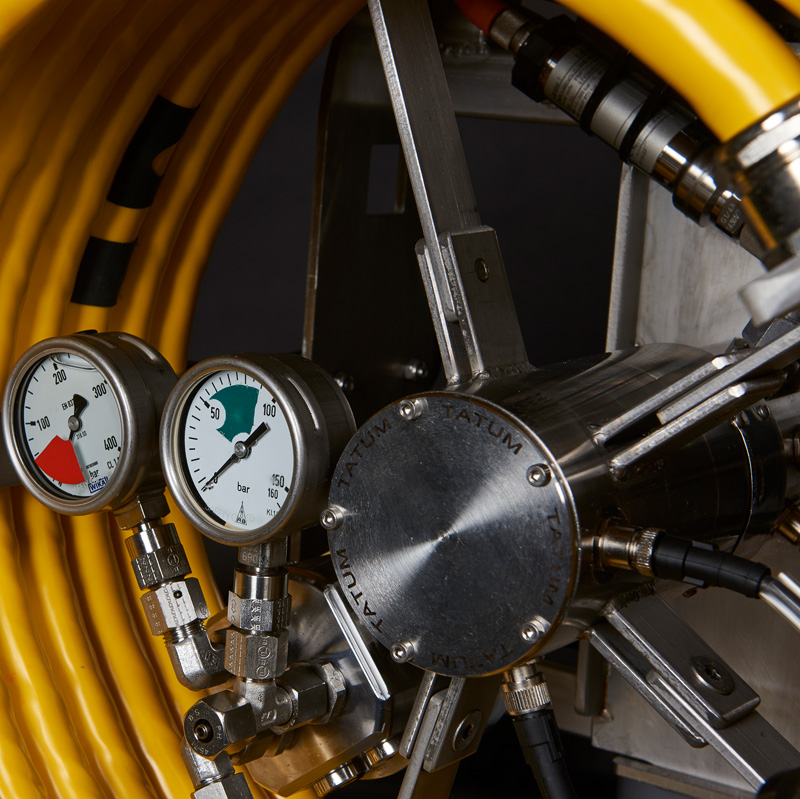

- Very high liter capacity of breathing air

- Variable, underwater adjustable air dosage between lung automatic or constant volume control

- Constant positive pressure inside the helmet, even during inhalation

- No inner mask required

- Good climate control by automatic regulation or alternatively possible manual control of breathing air supply.

- Continuously low CO2 level inside the helmet

- Purging process with breathing air already during exhalation

- No additional head fastening necessary, because of form-fitted, tight fit

- Very large viewing window for optimal field of vision

- Good communication in both directions due to suppression of external noise

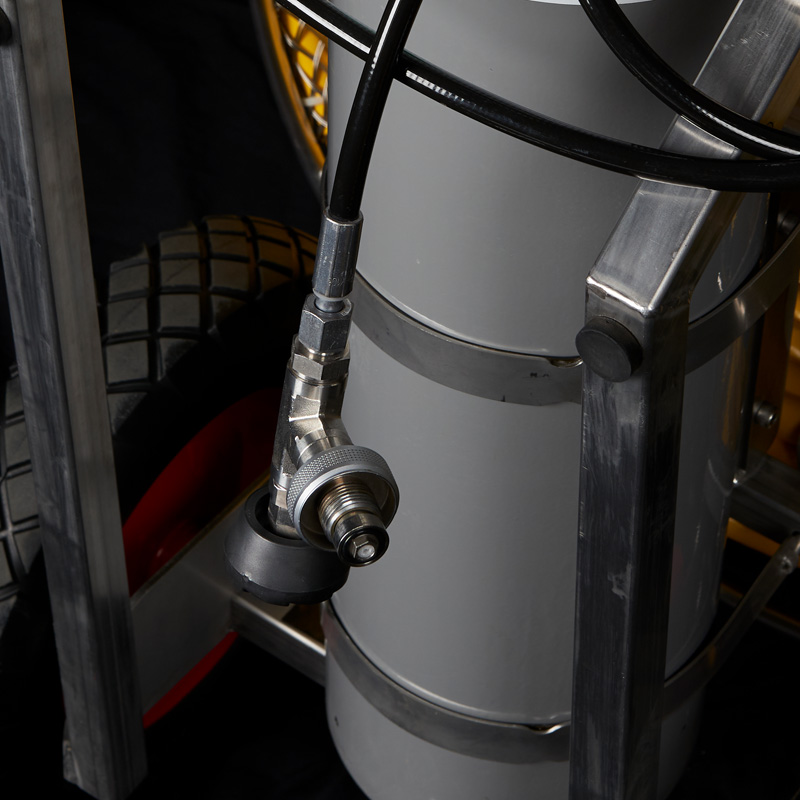

- Low risk of icing – the breathing air control is located inside the helmet

- Only a few components carrying breathing air come into contact with the diving medium.

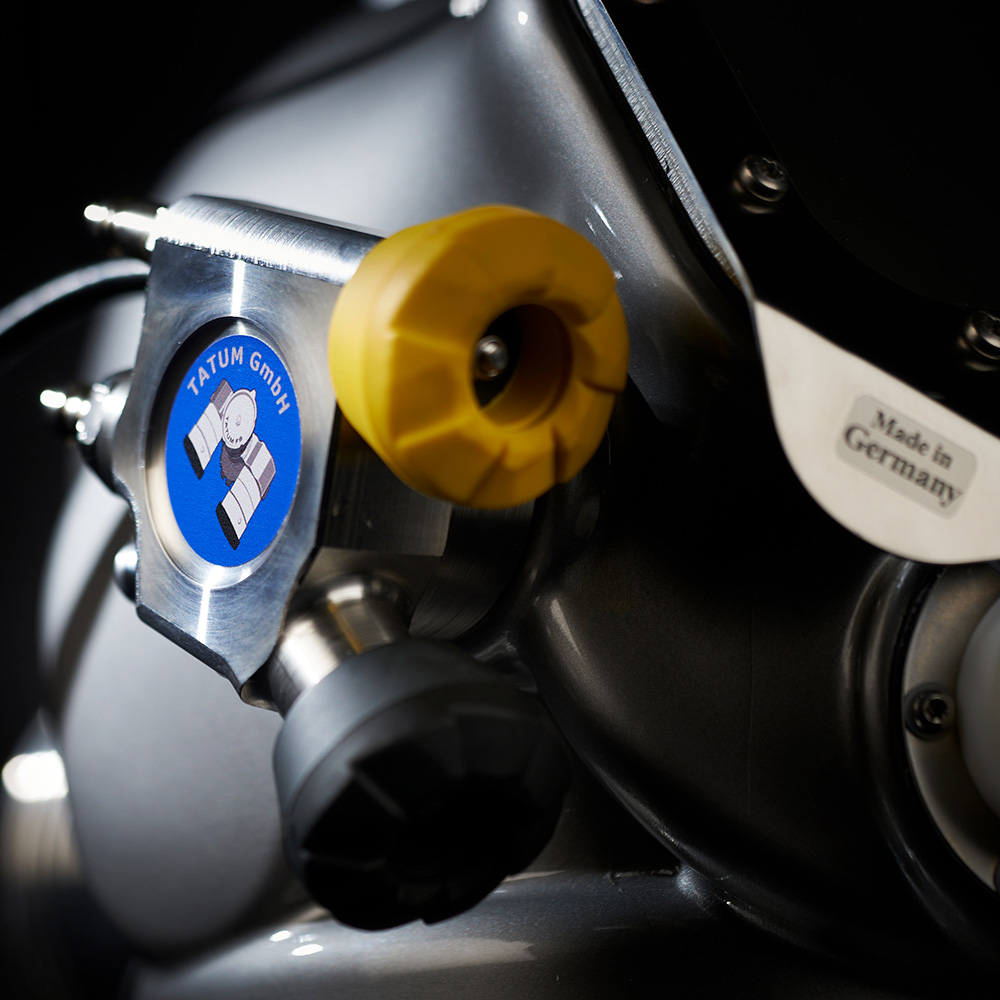

Reliability Made in Germany

- Low work of breathing, even with heavy workloads

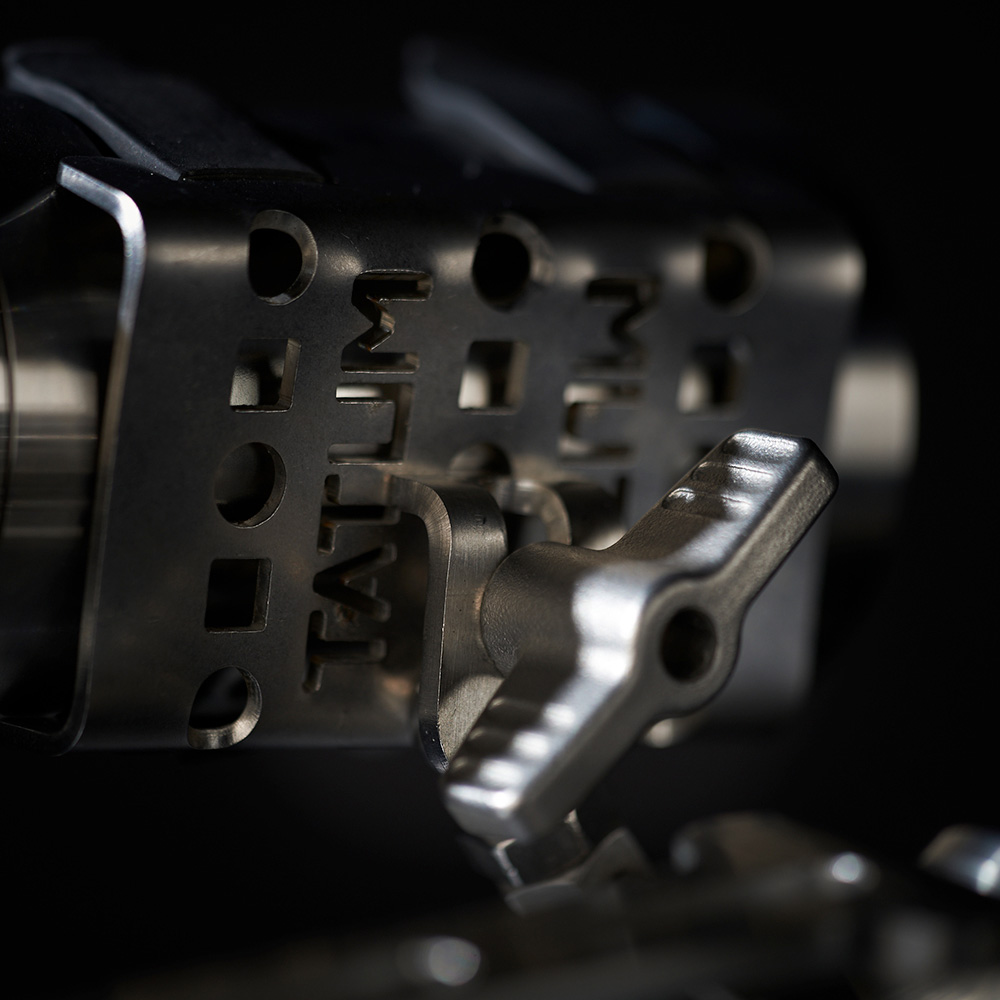

- Helmet shell made of GFK, reinforced with aramid fabric, fittings made of stainless steel 1.4571

- Easy, time-saving cleaning and disinfection

- Only few wearing parts

- Metric components

- Mostly commercially available tools can be used

- Low maintenance costs

- Regional, mainly own product manufacturing, Made in Germany

- Testing and certification in Germany